Milling and Manufacturing

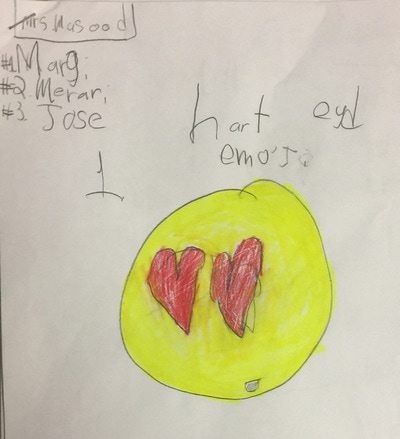

Given a drawing from a 4th grader at the local Lincoln Elementary school, my team and I set out to create it as a manufacturable toy.

Conceptualizing:

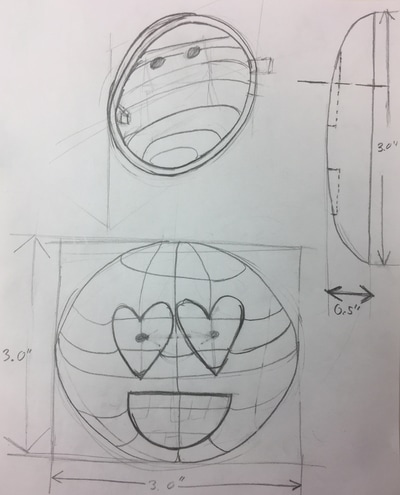

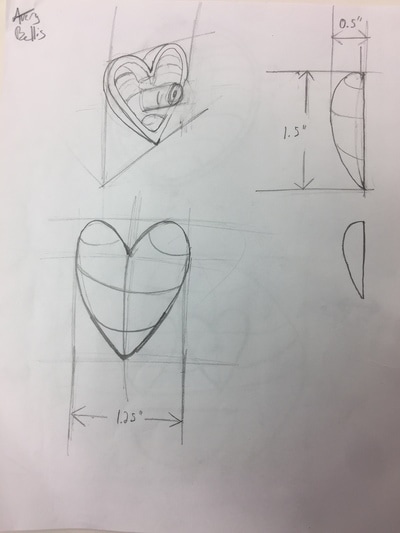

The first step we took was to sketch out what it might look like as injection molded parts.

Modeling:

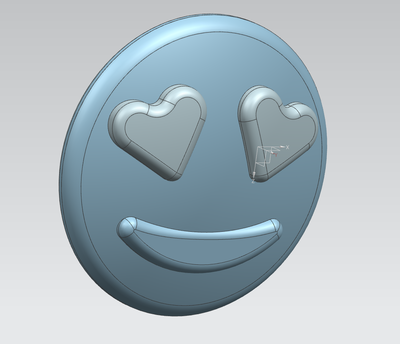

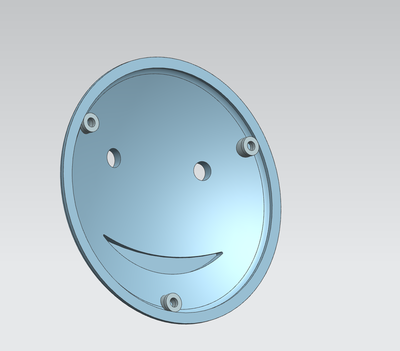

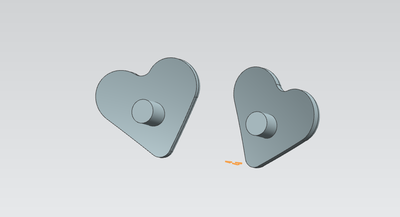

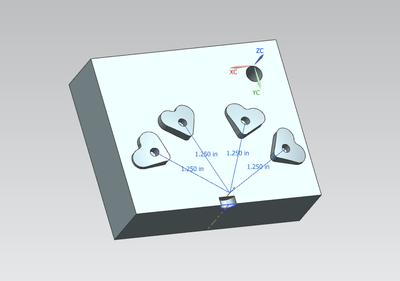

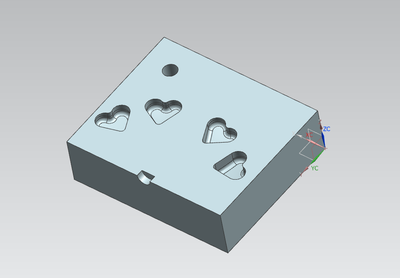

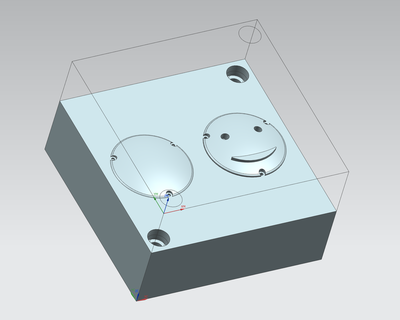

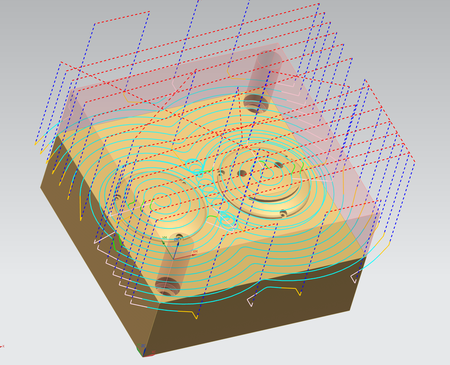

Next, we used NX to model all of the parts, and their respective core and cavity aluminum molds

Machining:

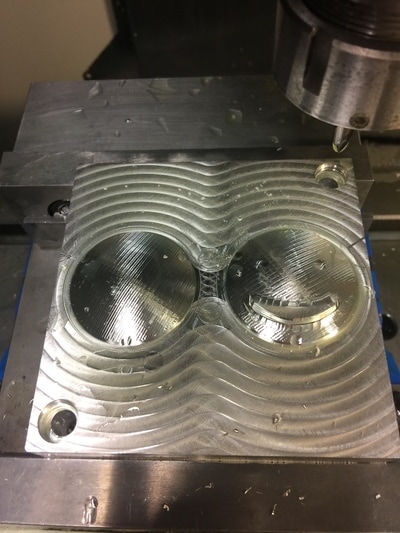

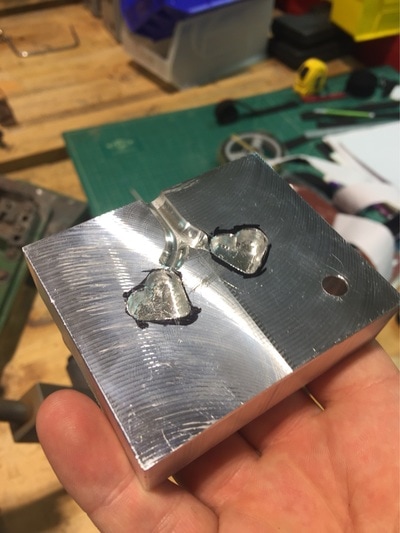

After completing all the computer work it was time to get in the shop and actually make our heart eye emoji molds

Manufacturing:

We produced over 100 complete toys using one industrial sized and one small injection molding machine. We measured a dimension of each parts to perform a control analysis.

Measuring:

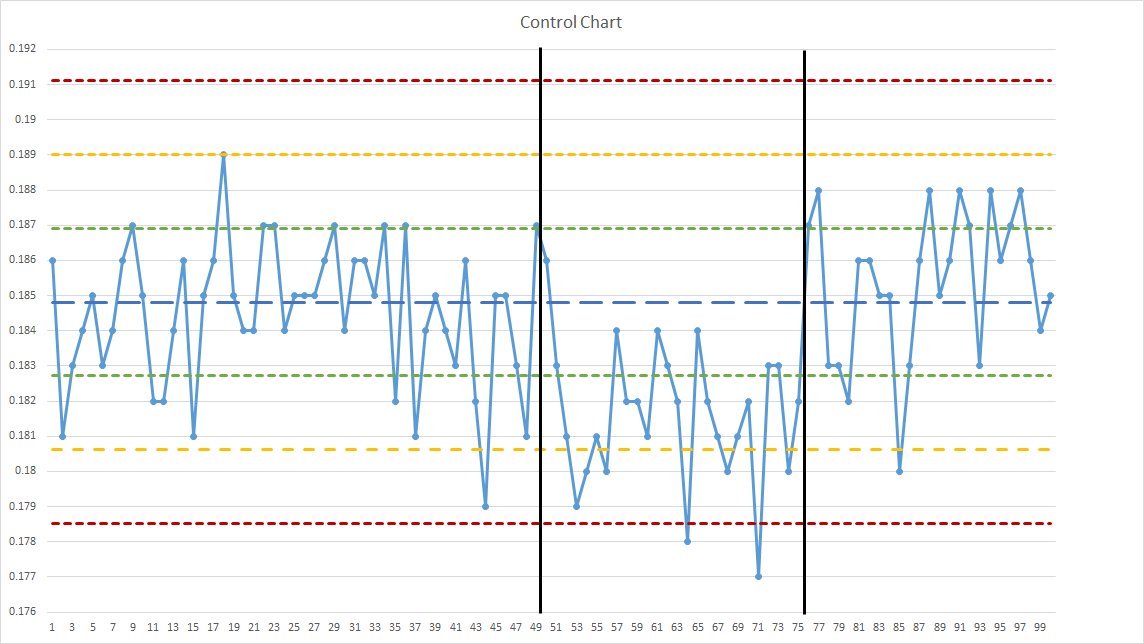

The diameter of the peg on the back of the emoji's right eye was a recorded control measure as we adjusted machine parameters.

We measured 100 consecutive parts. We adjusted the cooling time from 6 seconds to 3 seconds for parts 51-75 and returned it to 6 seconds for parts 76-100. The average diameter went from 0.185" to 0.181" and back to 0.185" respectively.

We were able to drive the production out of control by changing the cooling time.

Proudly powered by Weebly